-

Posts

2,220 -

Joined

-

Last visited

Content Type

Forums

Gallery

Events

Posts posted by Gary_Ash

-

-

Here are a few Studebaker woodies. None survive.

1937 Studebaker with body by U.S. Body & Forging.

1939 Studebaker woodie.

Studebaker M-series (1941-48) truck chassis with body by Hercules-Campbell. This one probably pre-war, based on stainless grille inserts.

-

6

6

-

-

At long last, here are the cast tops for the hub caps. They are Everdur bronze, about 3.2 lbs each. Very sturdy. They'll go in the mail today or tomorrow.

Have fun machining them to fit the cylinder pieces!

Bottom side of hub cap ends.

Tops of hub cap ends.

-

5

5

-

-

There were locomotives that ran on compressed air or stored steam.

https://en.m.wikipedia.org/wiki/Fireless_locomotive-

2

2

-

-

Google for truck springs shop in Seattle or nearby. Most of them can make new springs to match your old ones. They can also re-arch your old springs, perhaps retemper them. A spring shop should be able to make one new leaf to replace the broken one. I found Gitt Spring in Auburn, WA. https://gittspring.com/

Also, check with Eaton Detroit to see their prices on new springs. They may have the drawings to make them or you can get drawings from the Studebaker National Museum. Excellent quality. https://www.eatondetroitspring.com/

Good luck.

-

Luna Industries in Tucson can rewind your generator to deliver 12 volts. They can supply a new regulator for it, as well.

Most generators will fit in a USPS flat rate box. Just put in enough packing so it doesn't roll around and tape up the box well. Cheapest way to ship a heavy item.

-

20 minutes ago, alsancle said:

In the background is the Wheeler and Schebler Carburetor Company, maybe at the Indy Speedway in those days.

See the Wikipedia article on the company. Interesting!

P.S. Here is the story of Jules Goux.

https://en.wikipedia.org/wiki/Jules_Goux

-

1

1

-

1

1

-

-

Once you figure out what size you need, you can probably buy one here:

If you sort A > Z, you'll get all the sizes beginning with a 1 (including 10, 11, and 18) but eventually get to 2's and 3's. Price should be under $5. Keep scrolling!

-

1

1

-

-

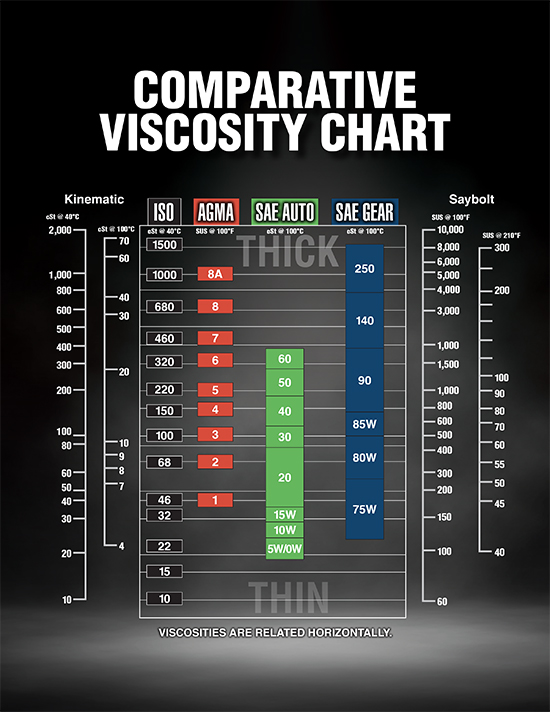

Remember, too, that gear oils and engine oils are rated on a different SAE viscosity scale. Here's a chart from the Amsoil web site:

-

1

1

-

-

It's unlikely that Ford developed the system themselves, so the mystery is which company did make it. I wouldn't expect Ford to provide any support for an installation in my Expedition but maybe the supplier would.

I found this wireless system today: https://www.tadibrothers.com/products/7-monitor-with-wireless-mounted-rv-backup-camera

I worry a bit about having the transmitted signal get out of the windowless aluminum trailer, but the floor is plywood, so maybe it would work OK. Upgrading to a higher powered system would probably help. They have the standard 75 ft range version plus a 95 ft and 125 ft version.

-

13 hours ago, kiwitony said:

Modern types of oils are not suitable for this age of car.

Please tell us why you feel that way. Generally, modern oils are vastly superior to those of 1925. My 1925-1928 Studebaker service book merely says use "a standard grade of oil from a reputable company", lighter oil in winter, heavier in summer. In the U.S., SAE established standards for grades 10-50 in 1911, added 60 weight in 1926, 10W and 20W in 1934. A modern 10W-30 (or straight 30) oil should be fine for the engine. There are many suppliers of oil made for synchromesh transmissions with brass or bronze parts for your transmission. The 1925 service manual says to "use a very heavy transmission oil or light transmission grease in warm weather", and fill to the height of the filler plug hole. The rear axle should be fine with standard 90, 90W, or 80W-90 gear oil.

Other opinions welcome.

-

I tow a 20 ft enclosed aluminum trailer with my 2022 Ford Expedition Max (long body version). Even with extra mirrors, it's hard to see what is behind the trailer. Backing up is also difficult when I'm alone. So, I'd like to mount a TV camera at the rear of the trailer above the door/ramp and have a screen in the cab of the truck. I have read that wireless cams using Bluetooth may not have enough signal strength to produce a good picture. I haven't seen a camera advertised that works with a cable, especially one with a connector at mid-cable so it can be disconnected when I unhitch the trailer.

Any suggestions of brands and models?

-

1

1

-

-

29 minutes ago, Terry Wiegand said:

t all possible I would like to contact this company and see if they could strip and replate the grille for me. This seems like a reasonable request to me.

Sorry, Terry, but it is not a reasonable request. When vendors set up to do hundreds of thousands of parts, they invest a million or two in a machine to do it, build all the tooling to handle the special parts, train a team of people, and hope to make a few bucks on coating a lot of identical parts. By now, the tooling doesn't exist, the team is long dispersed, and the company has moved on to other products. I spent most of my career in the vacuum coating industry and watched as technology came and went. It will be a growing problem for car collectors that it is nearly impossible to reproduce processes used decades ago, especially for plastic parts and older digital systems.

-

3

3

-

-

The older "chromed" knobs from the 1940s through at least 1980s were really vacuum evaporation deposited aluminum covered with a clear lacquer. It was fairly low tech but there are tricks to getting the coating to stick to the plastic and protecting it with lacquer so it doesn't oxidize or rub off. These days, the deposition can be done by vacuum sputtering aluminum or chrome, though the aluminum will always be brighter. Sputtered materials adhere well and tend to be harder, more durable coatings. The tough thing is to find someone who will do just a few parts for you at low cost.

-

1

1

-

-

Let's look at some math. There are 8760 hours in a year, so 8760 hours x .0000002 amps = .0017 amp-hours, not enough to drain a battery any time soon. Even if you meant 0.2 milliamps, that is still only 1.7 amp-hours in a year, not a lot. However, standard lead-acid batteries do have an internal discharge rate, though you can't measure it directly, probably above 10% per month, especially for an old battery. An Optima glass-mat battery will have a lower internal discharge rate, better when a car sits all winter.

-

1

1

-

-

From a July 1926 edition of Country Life.

-

4

4

-

-

On 4/27/2023 at 11:10 AM, StillOutThere said:

Aren't these factory equipped with Dana 44 axles if I recall? So wouldn't an ratio change if desired be quick, easy, relatively inexpensive?

It's probably a Dana 41, not 44. To change the axle ratio, it's not just the ring and pinion gears, you also have to have a different carrier. Those gears and carrier are unobtanium. Installing an overdrive transmission is an easier purchase and provides better drivability, especially with a low-powered engine. Studebaker cars and 1/2-ton pickups of that time period used the same parts

-

1

1

-

2

2

-

-

Harold Lloyd didn't always do well with cars...

Video (maybe painful for fans of old cars):

-

1

1

-

1

1

-

-

Is that comedy actor Harold Lloyd in the photo above?

-

2

2

-

-

A not so funny thing: I discovered I am too old to even be a Boomer!

-

2

2

-

-

For years, Studebaker and Pierce-Arrow fans have debated about whether the straight eight engine blocks were cast from the same material. Both were cast in the Studebaker foundry in South Bend. To answer the questions, I am trying to obtain pieces of engine blocks for both brands and have them chemically tested for alloy content and hardness. The X-ray fluorescence method will be used for alloy analysis, Rockwell tester for hardness.

If someone has a Studebaker 337 block that is dead or broken, I'd like to get a piece 2" x 2" or larger. I'm working on getting a piece of a P-A block. The samples will be sent to a professional test lab with the measurements made by one person on one day with the same instrument to eliminate technique, calibration, and sensitivity differences. I'll publish results in the Antique Studebaker Review and on the AACA Forum.

Have you got an old block?

-

3

3

-

-

-

@Reynard When I had the garage built, it was insulated with fiberglass having paper backing. I knew that the exposed paper backing was a real fire hazard and quickly put up the 5/8" OSB paneling with drywall screws, heads exposed. A couple of times, I have had to take down a panel to add wiring in the garage, very handy that the panels can be removed easily. Since the screws went into the studs, it's easy to see where heavy things should be hung. Lighter things do just get screwed to the OSB wherever I want.

I did buy a steel fire-resistant cabinet designed for solvent storage and keep acetone, paint thinner, and lacquer thinner in the cabinet. No gas cans stored in the garage, ever. But, three cars do have enough fuel in their tanks to destroy the garage if there is ever a fire. I have dry powder extinguishers and a 10 lb CO2 extinguisher. Since dry powder extinguishers will make a terrible corrosive mess, spending the money on the newer Halguard extinguishers from H3R is recommended, perhaps augmented by some Element sticks. I haven't put a smoke detector in the garage, but now that I think about it, I will. There are now Alexa-enabled smoke/CO detectors, sounds right for my detached garage.

Some years ago, a local boat manufacturing shop had a 55 gallon drum of acetone in the shop. A fire set it off and blew the building sky high.

-

In my 24 x 36 ft garage with 2x6 studs, I insulated the walls and installed 5/8" OSB panels. My intent has been to paint the panels with fire retardant/fire resistant paint, but I confess I have not done so yet. It may be time to do that. I like the OSB because I can screw things to the wall.

-

I haven't found a local college or university with an XRF tester. The instrument costs about $40,000. I did find a lab in central Mass. that will do the testing for $75 a sample. Each test takes about 2 minutes, can measure presence of materials to parts per million range, though probably 0.01% to 0.1 % is more than enough. We would expect to see iron at 90+%, carbon at 2.5-4%, and silicon at 1 to 3%. The differences would be in the presence or absence of other metals such as nickel, chromium, vanadium, molybdenum, copper, titanium, zirconium, and manganese, things added to change density, hardness, pour viscosity, or other properties. I think maybe having them test Rockwell hardness could be another comparative test.

Now I just need the samples. Ideally, they should be 2" x 3" or larger and be mostly flat. The samples have to be very clean and should be polished to remove surface rust, etc. The gun-like analyzer is held to the surface for two minutes while an X-ray source in the analyzer illuminates the sample surface. So, who has some pieces of a broken P-A 8-cylinder block? I'll also need a sample from a Studebaker 8 block from the same 1930s time period. I think I have a 1965 Chevy 283 block that I can saw a piece out of for comparison.

With all the data in hand, maybe I could write another PhD thesis...

XRF analyzer in use.

-

3

3

-

Transmission weight, 1931, 60-80-90 series

in Buick - Pre War

Posted

I don’t think GL-4 fluids or anything with “extreme pressure “ additives are correct for 1930s (or later) transmissions with brass or bronze parts. The extreme pressure lubes will damage yellow metals. A better choice is synchromesh transmission fluid. Generally, straight 50 weight engine oil also works fine in old transmissions. The extreme pressure stuff is for ring-and-pinion gears in rear axles where the gear surfaces slide against each other.