-

Posts

450 -

Joined

-

Last visited

Content Type

Forums

Gallery

Events

Posts posted by jazzer3

-

-

I have the same problem and I agree with F&J on the problem. If the car starts fine after the initial start after the few day rest I would bet on fuel evaporation.

-

Hello, I have experienced a blocked (NOS muffler with installed nest) exhaust system, another time late ignition timing. Both events the engines got hot in a short time.

-

Hello,

I have a trunk handle that when locked the square shaft only locks up in the unlock position and seems to be slipping over something it is not supposed to be slipping over when turning in the direction to lock the trunk. The other handle is completely free of the square shaft when unlocked and locks up in both directions in the locked position. Is this a common problem and is it serviceable?

Also the wheels of our car has what appears to be nice white paint under a thin coat of black paint, I used a lacquer thinner dampened rag and removed some of the black paint, (which does come off easily), and the white paint seems to be unaffected by the thinner as I see no white pigment on the rag. I really am not looking forward to doing four wheels with a lacquer thinner rag but am afraid a paint stripper will affect the white paint can anyone recommend anything more user friendly than lacquer thinner.

Getting the C-10 ready for a trip!

Thanks,

Jay

-

Posted Today, 04:59 PM

This kickdown switch was in the oven at 500 F for a while then I drove a previously prepared wedge Gently between the block and switch, I had an old carburetor that I put a propane torch to and found that it melted above 500F, using a "temple stick" something welders use to check welding temperatures.

Your situation appears a bit more involved, maybe with some long machine screws a flat surface and some heat it might work.

Good luck,

Jay

-

This kickdown switch was in the oven at 500 F for a while then I drove a previously prepared wedge Gently between the block and switch, I had an old carburetor that I put a propane torch to and found that it melted above 500F, using a "temple stick" something welders use to check welding temperatures.

Your situation appears a bit more involved, maybe with some long machine screws a flat surface and some heat it might work.

Good luck,

Jay

-

Yessir, I have some in position. The Studebaker is "trying" to drip on the airflow

.

. -

Hello, I purchased 2 extra tall lifts, they are rated at 8000 lbs. but don't think it will ever get that close. One is together which I did alone so I could take my time, the second I will enlist some help now that I'm familiar with the assembly. The lifts were purchased from "best buy" because they were the first to have them available, I think they might also have the lowest price for a comparable lift. There are no "Made in USA" stickers and the manufacturer wasn't proud enough to note where it was built but being a fabricator of sorts I saw nothing in the build quality that upset me.

As of now there is a 57 Studebaker trying to drip it's fluids onto a 36 Airflow.

No photos as I lost my phone a month ago and it took lousy photos anyhow.

Jay

-

Thanks so far, padgett's question as to why "years" made me rethink my storage plans, thank you. I was thinking of putting our "future projects" out of the way(up top). Four operable cars loaded onto the lifts makes much more sense.

We have eight older cars that are operable and two buildings each with two doors. Five of the cars are easily gotten out three take some manuvering involving dollies and a floor jack. This past summer seven of the eight got driven, the eighth stayed put only because of the trouble to get it out. If no more cars are purchased the addition of the lifts will greatly enhance operating room floor space.

No earthqukes around these parts yet!

Jay

-

Hello, I am asking for advice on auto lifts. I need to put two cars up and two under, a double wide four post lift would do what I need for about $6,000, but two separate single car lifts end to end would be better suited.

I have an area 12' wide by 38' long and 13' heigth where the lifts would be located.

The cars up top may be there for years, maybe. If you have done it and were going to do it again what would you do?

Would two post lifts work or stick with four post lifts, I am thinking the four post might be safer for long term storage but I do have a friend that always has a car up on his two post lift.

Our shop floor is 6" concrete reinforced with wire.

Thank you,

Jay

-

Hello here's a Bugatti update, the original front leaf springs gave up at the end of last year, from the beginning their quality was suspect, late this summer I ordered low-grade spring steel from McMaster Carr and made some new springs. They aren't chrome plated as original but they have a nice blue tint, and they work, the old springs would sag after a little while so's the frame would be setting on the axle. They would get rearched by picking the car up and pushing the axle down, .

The throttle pedal is moved all the way forward and our 8 year old is a little tight, inorder for him to drive it next year the throttle pedal would need to be moved up beside the steering linkage, instead we are going to put an older 1/4 midget together for him and the Bugatti can be for the younger youngins.

I recently saw a few "operating Bugatti replicas" for sale that closely resemble our car. The prices were quite impressive.

Jay

-

I've driven the Commander about 100 miles so far. It drives nicely on the road but there may be some transmission issues. I did drop the pan and clean the screen but maybe should have done some additional cleaning. It seems to me that it doesn't go into a lower gear until after you pull-out from a stop, it might struggle a bit on some starts especially if uphill and will then downshift after moving. The more it is driven it seems to work better and I suctioned out a pint of trans fluid and added a pint of sea-foam to see if things work better. I did have the carburetor off but was careful not to disturb linkage adjustments, this is the first older car with an automatic transmission we have had since a 56 Plymouth back in 1976 and I'm not used to all this linkage and adjustments

Thank you Ken for the rear window and Mary Ann and Bill for a straight front bumper.

Although the transmission may require removal I am tickled at hoe the Commander works otherwise and deem it worthy of finding a carpet kit, the painted steel front floor should be covered.

Thanks all,

Jay

-

If Joe doesn't have enough I have a few I can spare.

Jay

-

Hello I would like to tell you about our 48 Ford Coupe.

This car has been in my neighborhood as long as anyone (those older than myself) can remember. The original owner lived down the street from me and I would go and study the car then go home and pick out items from the J.C. Whitney catalog for it.

When the Man passed away in 1968, I was 14 Yrs. old and was convinced nobody else was interested in this old car and had my Aunt making inquires. The car stayed in the family belonging to one sister until she passed and then to another sister, when she passed in 1970 a local undertaker got car, house, and who knows what else.

We go now to the spring of 2010, the undertaker dies and his nephew who is my friend is also the executor of the estate and I got the 48 Ford i wanted so long ago.

Once I got the car running, it hadn't been on the road for 7 years or so, it wasn't running on all eight, so doing some investigating revealed a valve guide retainer clip had come undone and 1/2 of the valve guide was free to move. The original engine was bored .030" and has no wear, I think this car has 185,000 miles on it.

A friend built me an engine a 221 inch 1942 engine which ran fine for a summer and one day I think I actually heard the cylinder wall crack, so that engine came out and another was built.

The car now has a 265 c.i. engine with headers and an Isky cam, stock heads and carburetor for now

I am in the process of modifying a stock intake to accept a Stromberg intended for a straight 8 Chrysler.

This thing is fun to drive and sounds great

Jay

-

One needs to watch out for that hood ornament, wiping polish off the hood. the back of the ornament and my hand met, it is as pointy as the front.

-

-

After buying seam sealer and undercoating to finish the job a spot just below the firewall insulator looked suspect so the tools came out and a piece 3 inches by 8 inches was welded in. I didn't grind any welds smooth as they were solid and looked good enough to me with a little dressing.

Now the interior gets a good cleaning and put back together.

Jay

-

-

Some rust repair was necessary and I needed to see, a four foot florescent light suspended on ropes works well.

Seeing is not a problem, here is what needs fixin.

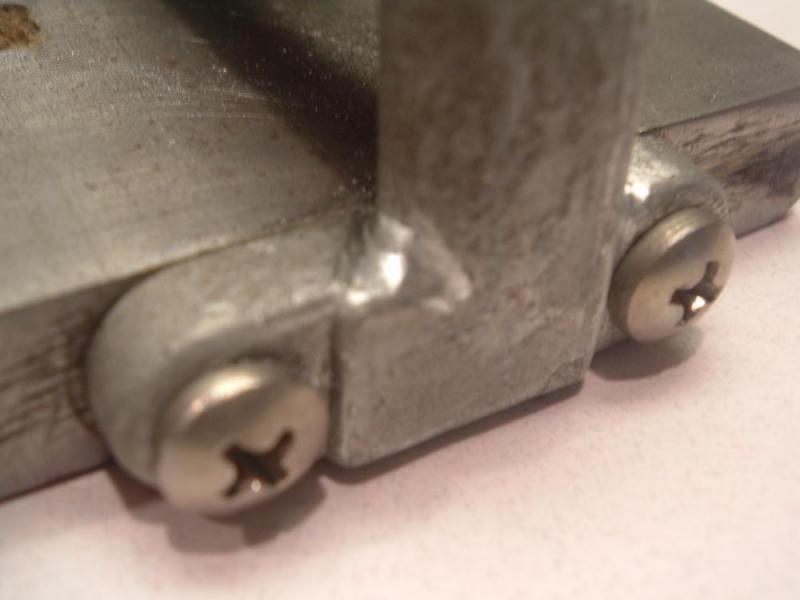

The new mount is welded in but the bottom of the new mount is made from one piece of 3/16" steel verses the original which appeared to be two pieces of thinner stock.

Had to rush home so no photos of what got done yesterday but it was a good day of progress. I wasn't sure what i was going to use to replace the mount but there is quite a pile of cut-offs that are kept for these problems. A short piece of 2" X 4" steel tube cut up provided the uprights for the mount. The rounded corners of the tubing closely match the radius of the original mount.

Jay -

Check the length of the wheel-cylinder push rods, the new rods may be a different length than the old push rods. If that isn't the case you may have to reposition the anchor-pins for the brake shoes this is covered in the service manual or the "Motors manual" describes how to do a major brake adjustment without the proper tools. On our 50 New Yorker I belt sanded the replacement brake shoes because I could not get the drums on, but I never checked the push-rod lengths. This was surely not the best thing to do as for accuracy and dust but I was careful and they work well.

Good luck,

Jay

-

-

Thank you Dan, our Airflow was redone quite a while ago and there may be parts from a few different cars that were involved in it's redoing. The wheels on it now appear to have been white and without having wide-whitewall tires on the car I thought it would look better with the contrasting white wheels.

Now there are more parts from more cars involved, the engine and transmission were out of the car and in pieces when we got it. In putting the engine together I have a 35 head, 37 intake manifold, 39 exhaust manifold, 50 distributor, the tappets and air filter mount came from Australia and the rings came out of a rebuilt 39 engine that was bought for parts.

Jay

-

-

Thank you Phil

-

Our 48 ford

in Ford and Mercury - 1932 to 1953

Posted

Modified stock ford manifold to accept a Stromberg intended for a straight eight Chrysler.

The Manifold was bored out to accept thin sleeves that have 1.4375 I.D.(to match the carb. I.D.) the manifold was heated in an oven, a household oven that was in a home, don't do this unless your wife is going to be away for weeks, to 500 F. and the sleeves were pushed into the intake. The holes in the block for the carburetor preheat were tapped and pipe plugs installed. The engine has a 400 jr. track cam and pulls strong from around 45 to about 70 mph. about time I lift due to the bias-ply 16 inch light truck tires. With the stock carbuetor there was enough vacuum that the wipers still operated with the bigger carburetor no. I bought a 6 volt electric wiper mtr. but have not installed it yet.

Jay